For Packaging Inspection

Solutions For Packaging Inspection

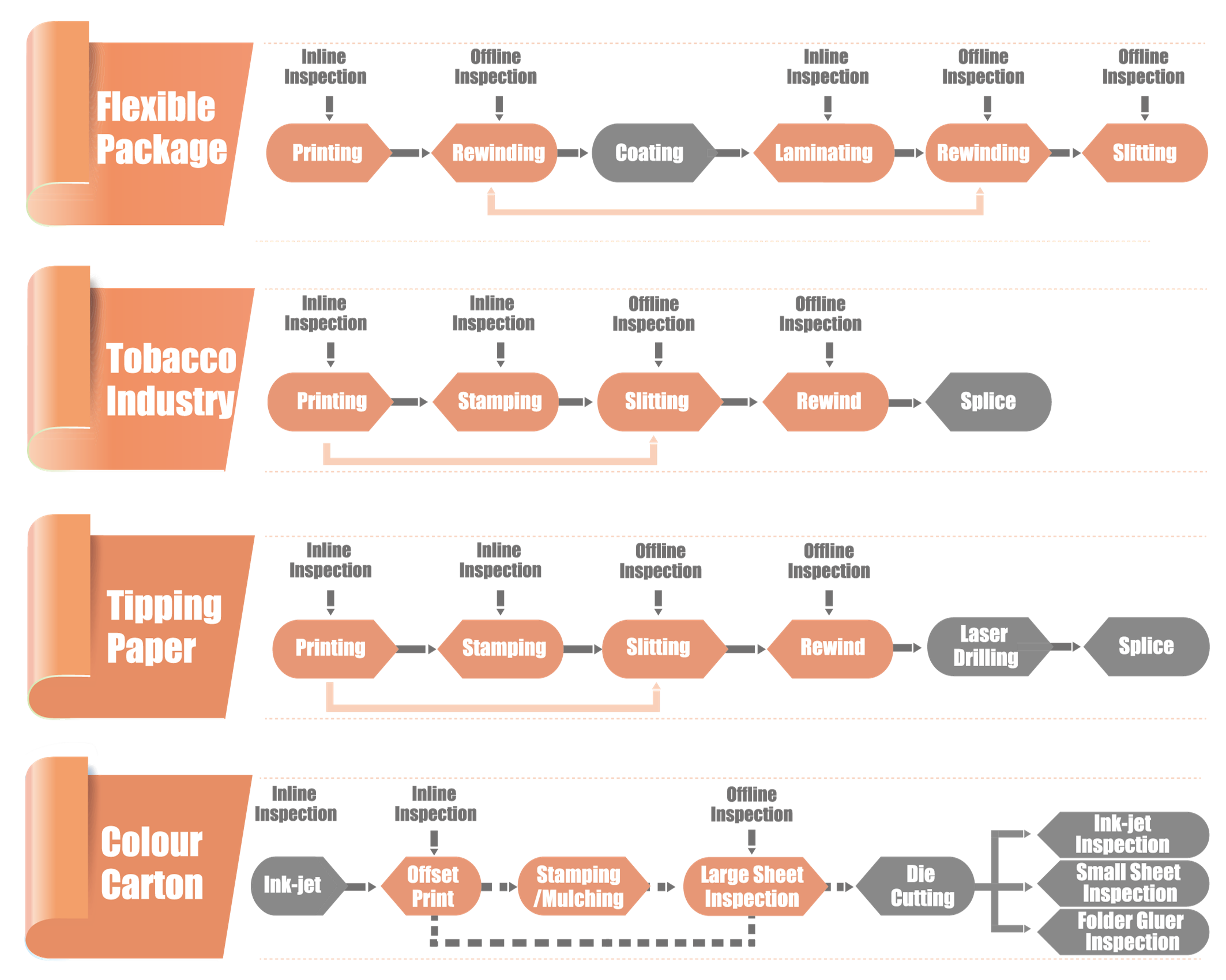

Luster provides flexible solutions of online and offline inspection and world class vision inspection products for packaging market such as flexible packaging, folding cartons, tobacco industry and tipping paper. From printing, stamping, slitting to rewinding, it can be applied on the whole workflow to control quality during and after production. With real 100% printing defects inspection and quality management, our solutions has proven to be effective in reducing labour cost and print waste, increasing productivity and efficiency.

Two series of products can be applied for package inspection-PackRoll series printing quality inspection equipments and PackSheet series printing quality inspection equipments. With advanced imaging system and inspection software, the PackRoll series are specifically developed for flexible plastic packaging, web tobacco packaging, tipping paper as well as other printed webs on any substrate. The online inspection equipments from PackRoll series can be installed on any press and stamping machine to do process control and reduce waste of raw material. and offline inspection equipments from PackRoll series can be installed on any rewinder and slitting machine to do final inspection for final quality assurance.

The PackSheet series are specifically developed for sheet-fed printed packaging inspection such as pharmaceutical packaging, cosmetic packaging, food packaging, tobacco packaging and other colour cartons. It can be installed on offset press, folder gluer as well as sheet-fed offline processing equipment and ink-jet equipment. Our imaging system allows it to effectively inspect defects not only on normal printed material but also on high reflective material such as laser, hot stamping, hologram etc..

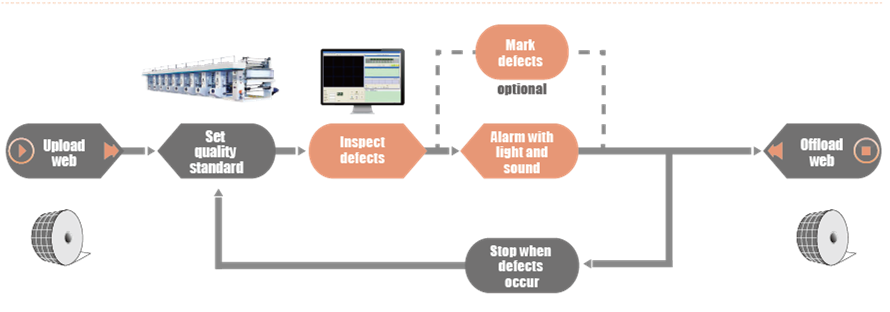

1. Online Inspection Solution

A. Installed on any press.

B. Reduce continuous waste.

C. The printing quality can be modified with quality reports.

D. Real-time defect light and sound alarm.

E. Alternative markers help users mark the flexible package with defects.

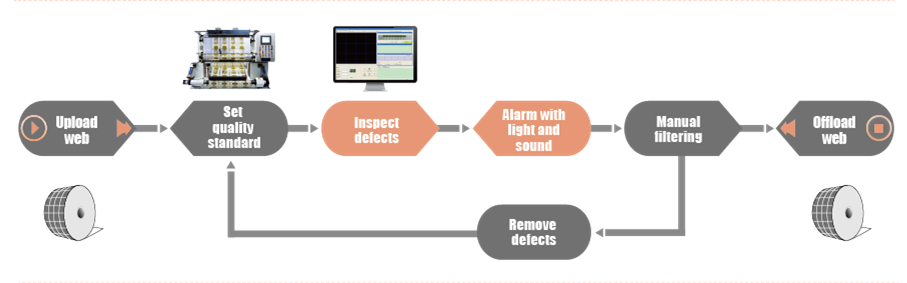

2. Offline Inspection Solution

A. Mainly installed on rewinder and slitting machine.

B. It is effective on inspecting defects such as dirty spot, missing print, foreign object, splash, streak etc..

C. Removing defected packaging based on pre-set quality standard.

D. Guaranteeing the final product quality and decreasing customer rejection.

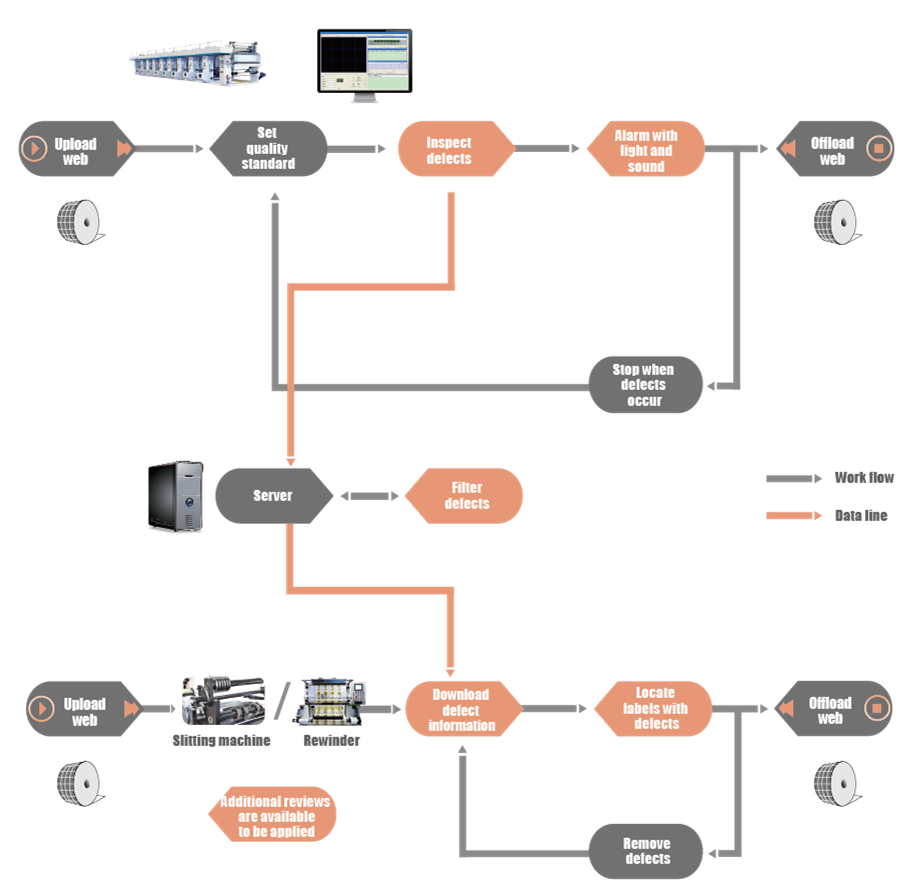

3. Solution of Online Inspection and Offline Replacement

A. Splitting the traditional integrated module (inspecting + filtering +removing) into separated units.

B. Online inspection module also functions of vision inspection, defects filtering, quality monitoring, data report etc..

C. Users can download the filtered defects data to PackRoll offline equipment to remove all the defects.

D. Reducing waste, assuring product quality and enhancing the whole work efficiency.

Common Defects

Missing Print Dirty Spot Scratch Streak Mis-registration Crease